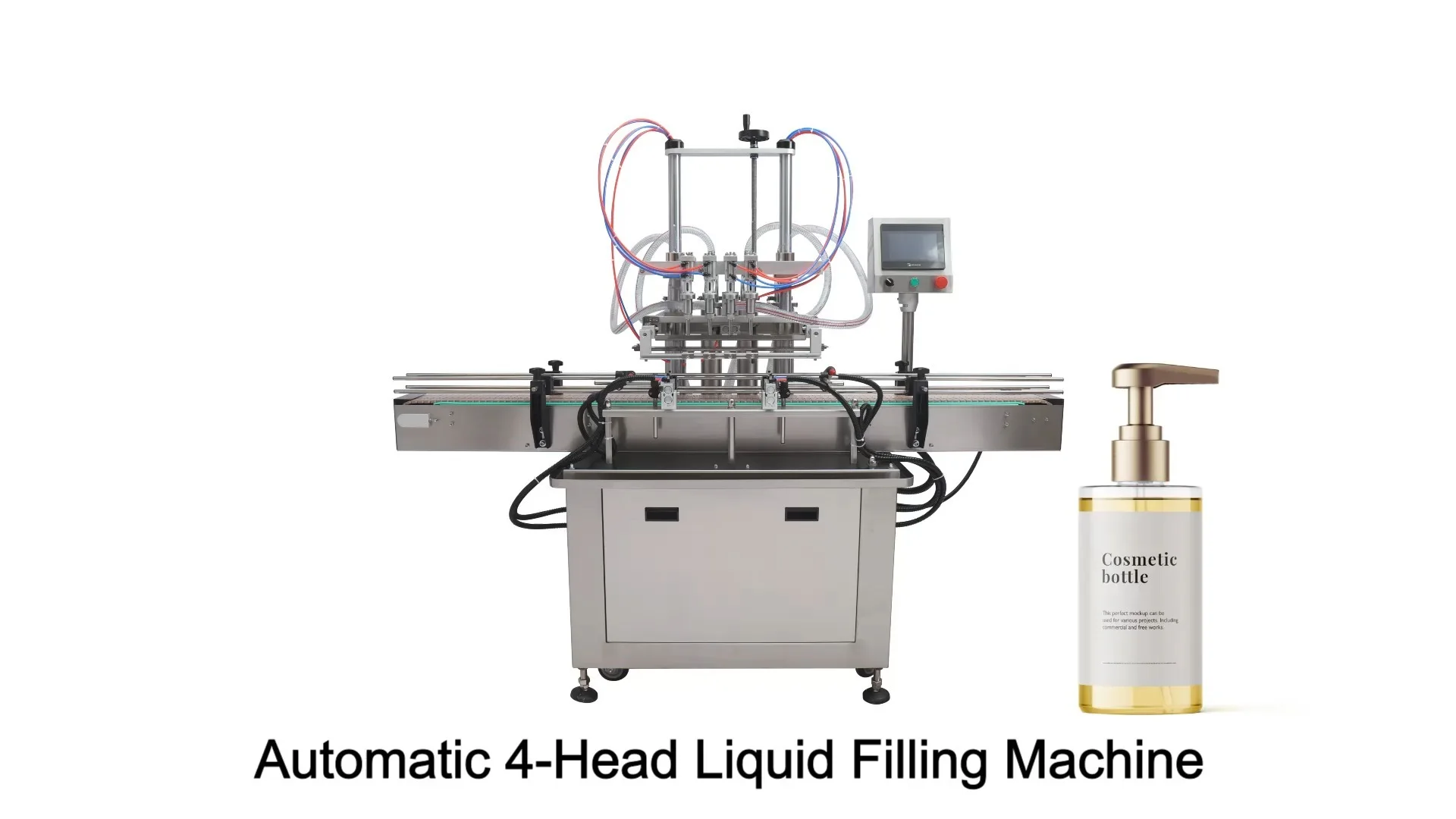

Automatic 4 Head Water Bottle Liquid Filling machine

Features

Filling volume:

10-100/30-300/50-500/100-1000/200-1500/300-2500/1000-5000ml

This machine is a standard model, if you need to customize, please contact sales.

Technical Parameters

|

Industry-specific attributes |

|

|

Machinery Capacity |

1000BPH |

|

Packaging Material |

Wood |

|

Filling Material |

Milk, Water, Oil, Juice, liquid |

|

Filling Accuracy |

99% |

|

Other attributes |

|

|

Application |

Beverage, Chemical, Commodity, Food |

|

Packaging Type |

Cartons |

|

Automatic Grade |

Automatic |

|

Driven Type |

Electric |

|

Place of Origin |

Zhejiang, China |

|

Weight |

200 KG |

|

Warranty |

1 Year |

|

Core Components |

Pressure vessel, PLC |

|

Voltage |

220V 50-60HZ |

|

Dimension(L*W*H) |

2000*1050*1600 |

|

Key Selling Points |

Automatic |

|

Air pressure |

0.6-0.8Mpa |

|

Conveyor length |

2m |

|

Required air compressor |

≥7.5kw 200L |

|

After-sales Service Provided |

Online support, Video technical support |

|

Certification |

CE Certificate |

|

Supply Ability |

5 Unit/Units per Month |

|

Lead time (days) |

To be negotiated |

Barrel

The barrel is made of high quality 304 stainless steel, which is food grade.

The size of the barrel is different for different filling ranges.

If the product is highly corrosive, 316 stainless steel can be customized.

Filling nozzle

The filling nozzle is made of high quality 304 stainless steel, which is food grade.

Customizable:

1. Up and down filling system

2. 2, 4, 6, 8, 10, 12 filling nozzles can be customized

Bottle Fixing Structure

The bottle fixing structure is composed of a baffle plate and a buckle, which is used to fix the bottle during filling.

Can be adjusted according to the height and diameter of the bottle, easy to adjust.

Sensor

High-precision bottle sensor, smart sensor bottle, no bottle no filling

Sensor sensitivity can be adjusted.

Sensor

High-precision bottle sensor, smart sensor bottle, no bottle no filling. Sensor sensitivity can be adjusted.

Filling Height Adjustment Wheel

Rotating the wheel can adjust the filling height to suit bottles of different heights.

PLC control panel

The control panel includes a touch screen, power switch, start button and emergency stop switch.

The PLC system controls the work of the machine, with high precision, high speed, and easy to adjust parameters.

PLC control panel

The control panel includes a touch screen, power switch, start button and emergency stop switch. The PLC system controls the work of the machine, with high precision, high speed, and easy to adjust parameters.

Filling cylinder

The filling volume can be adjusted by turning the wheel.

There is a scale on the cylinder, which can be used as a reference for filling volume adjustment. (the scale is not the actual filling volume)

Adjusting the throttle valve can control the filling speed.

Combination cylinder

Airtac air conditioning combination cylinders are used for air filtration, lubrication and air pressure adjustment.

Ensure the stable operation of the machine.

Combination cylinder

Airtac air conditioning combination cylinders are used for air filtration,

lubrication and air pressure adjustment.

Ensure the stable operation of the machine.